ADVENSER provides BIM services in the following domains:

MEP | Architecture | Structural | HVAC | Facade

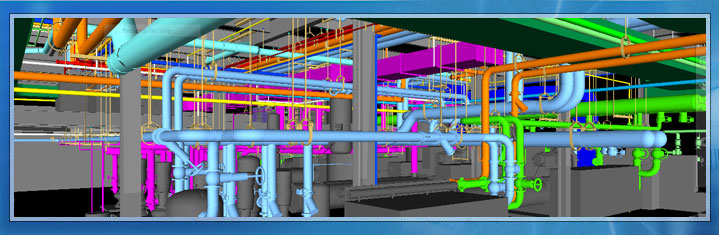

MEP / HVAC BIM Services

MEP HVAC BIM

Advenser offers full service solutions for all your MEP Building Information modeling requirements. We specialize in providing BIM services to the construction industry for many years.

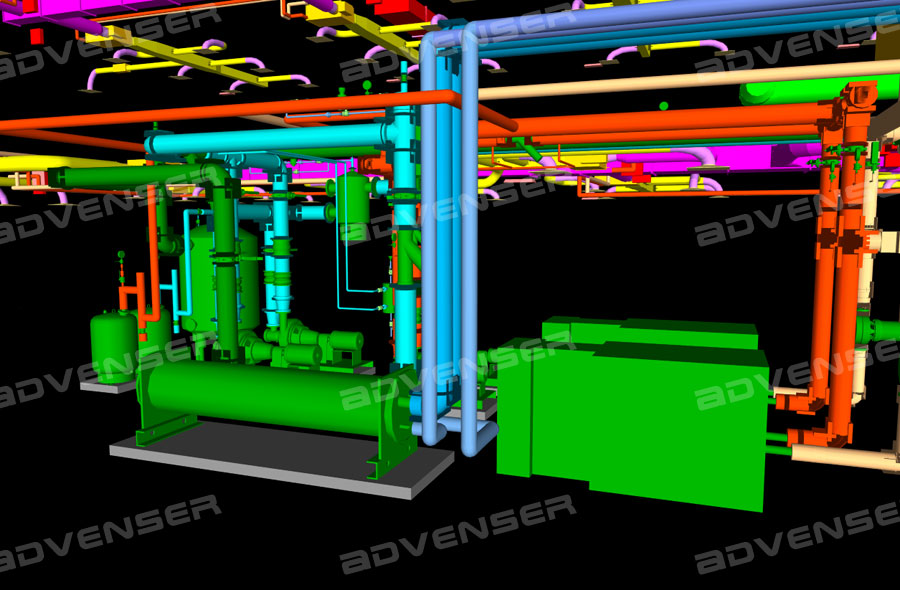

Every building structure necessarily requires mechanical, electrical and plumbing systems for the proper functioning as to get sustainability. Our MEP services enable the creation of a perpetual system and provides an effective synchronization between all the individual parts of the building. Our services include MEP 3d modeling, CAD Services, MEP Coordination, etc for residential, commercial, industrial and multi-purpose buildings.

Building Information Modeling (BIM) is a great tool for visualization. It enables a three dimensional virtual representation of the building. During a project’s bidding phase, renderings, walkthroughs, and sequencing of the model may be presented with better clarity. 3D Visualization with BIM provides a better picture what a structure may look like. It takes away the effort of bringing together the different 2D views by different trades.

BIM produces construction documents that like those created by 2D CAD Drafting, but are done much more accurate and faster. It contains information about structure, quantities, materials and other data that can be used in both — the construction and management of a building. With the help of BIM, designers can analyze the building design in detail and track human errors. The fundamental difference between 3D CAD model and a BIM is that, 3D CAD model enables visualization of a structure, whereas BIM provides detailed & comprehensive information about how the building will function. The use of BIM especially improves the collaborative efforts of the team.

BIM can reduce to a great extent, the errors made by design team or the construction team (Contractors and Subcontractors). The construction manager can provide constructability, sequencing, value and engineering reports. They can also start 3D coordination between subcontractors and vendors from the early stages of design. It enables the use of conflict detection by informing the team members about services of the building which are in conflict or clash by means of detailed visualization. Error reduction is a great part of cost savings realized by all members of a project. Reduction in time required to complete construction directly relates to the cost savings as well.

BIM facilitates the sharing of the model among the engineer, architect, construction manager, and subcontractors as well. During the BIM meetings, the construction manager and subcontractor can share their expertise with the design team. The construction manager can also use the BIM models to generate constructability reports, contractors and steel fabricators need to spatially coordinate their work. The 3D coordination can be started right after the model is created to ensure that any same space interference (hard clash) or clearance clash (soft clash) conflicts are resolved. After the completion of collaboration tasks like MEP coordination, specialty contractor can then use this BIM Model to prefabrication. Walls, rooms and houses can be prefabricated with roughed mechanical, electrical, plumbing (MEP) components. Final MEP connections can be made once the prefabricated components are assembled onsite. BIM enables an integrated project delivery and thus sharing of risk and reward by all parties involved.

BIM enables coordination between casework installers and MEP contractors. Pipe manufacturer could use BIM to gather coordinated piping locations, lengths and sizes for its fabrication software as long as the interoperability is possible. This allows in-wall drops including hot, cold, drain/vent, vacuum, etc. to be prefabricated.

Preliminary Design

Once the overall shape and form of the building envelope are established, the design teams often focus on area and space planning—allocation of available space within the building envelope to the various program needs and considering various layouts for how these spaces might be best organized or utilized.

Typical articulation of features of the building envelope, proposing the exterior wall materials and assemblies, preliminary window placements, day lighting and shading features, and the roof form will happen in the initial stage of design. Preliminary room layouts are also be created to develop the scheme for the interior spaces that will be used.

As and when information about the proposed design is refined and improvised to the building model, analysis of the proposed design can continue to guide the design. For example, during the initial design phase, cost estimates are often developed based on the quantities and materials mentioned in the model. These estimates provide valuable feedback that helps design teams evaluate the impact of potential design decisions and ultimately make better decisions.

Design Development

The ideas and design features approved during the preliminary design phase are developed and explored in more detail during the design development phase.

For instance, once the approval for room layouts have been procured, a wide variety of interior details and finishes can be added to fill out the design. Design alternatives for casework options and fixture placement can be taken into account. Evaluation of special architectural treatments for interior walls or ceilings can be executed. Though these features could have been added during an earlier phase, it makes more clarity and reduces the likelihood of wasted work to add them after the preliminary design phase.

Evaluation of design options is also part of design development phase. This involves identifying key features where the design develops and explores several alternate approaches. The versatility of the BIM modeling process allows the design teams to develop alternate design ideas and evaluate them in the context of the overall proposed design. Teams will have greater latitude to test new ideas and find better solutions by making it easy to consider design options.

Analysis of the building model can continue at greater detail during the design development phase. Cost estimates may be updated and refined. Various analysis tools can be used on the building model to help teams in producing preliminary designs for the structural and building systems (mechanical, electrical, and plumbing systems), and the impacts and interactions with these systems can be evaluated and utilized for improving the design proposed by the team.

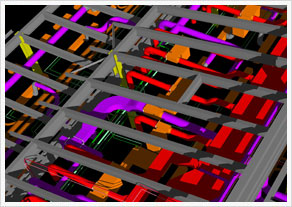

Construction Documents and Details

The construction documentation and detailing phase emphasizes on adding information to the building model for a comprehensive description of the proposed design through drawings and details that can be used to assist in the construction process.

A comprehensive documentation of the proposed design at the level of detail required to guide the construction process can be an immensely difficult task. The documentation should cover every feature of the building assemblies, the connection details, and the components that will be installed and they be presented on sheets for distribution to the project delivery team.

There are several ways for BIM tools to be utilized during this phase of the design process. A model of the building with an overall framework for generating the details must be created. Views of the building model can be created that becomes the base for details rather than drawing each detail from scratch as a series of lines. Annotations and notes are added to completely explain these details, but the building model acts as a valuable starting point and serves as a consistency check. As the model views are live, changes to the building model are automatically reflected in the derived details.

The output of the construction document phase is typically a set of printed plan sheets. The building model can be shared with the project delivery team to enable automated quantity takeoffs as well as for solving conflicts and interference checking in the drawing. This effectual BIM design application process mandates new approaches to organize project teams, share risk and Integrated Project Delivery.

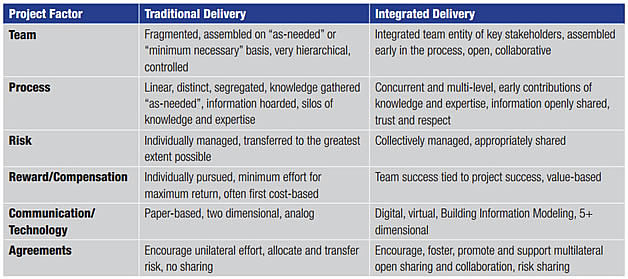

Integrated project delivery ( IPD) is a revolutionary way to excel your construction management by minimizing wastage, reducing costs and improving productivity. The main goal of the Integrated Project Delivery main goal is to create a team effort in bringing together the owner, architects, engineers, managers and subcontractors on the same platform. The Integrated Project Delivery creates an unique bond from day one of the planning stages and binds all key players for the project development.

A comparison of traditional delivery methods vs. Integrated Project Delivery (IPD) methods

The various BIM supporting softwares are :

Product Name |

Manufacturer |

Primary Function |

Cadpipe HVAC |

AEC Design Group |

3D HVAC Modeling |

Revit Architecture |

Autodesk |

3D Architectural Modeling and parametric design. |

AutoCAD Architecture |

Autodesk |

3D Architectural Modeling and parametric design. |

Revit Structure |

Autodesk |

3D Structural Modeling and parametric design. |

Revit MEP |

Autodesk |

3D Detailed MEP Modeling |

AutoCAD MEP |

Autodesk |

3D MEP Modeling |

AutoCAD Civil 3D |

Autodesk |

Site Development |

DProfiler |

Beck Technology |

3D conceptual modeling wi |

Bentley BIM Suite (MicroStation, Bentley Architecture, Structural, Mechanical, Electrical, Generative Design) |

Bentley Systems |

3D Architectural, Structural, Mechanical, Electrical, and Generative Components Modeling |

Fastrak |

CSC (UK) |

3D Structural Modeling |

SDS/2 |

Design Data |

3D Detailed Structural Modeling |

Fabrication for AutoCAD MEP |

East Coast CAD/CAM |

3D Detailed MEP Modeling |

Digital Project |

Gehry Technologies |

CATIA based BIM System for Architectural, Design, Engineering, and Construction Modeling |

Digital Project MEP Systems Routing |

Gehry Technologies |

MEP Design |

ArchiCAD |

Graphisoft |

3D Architectural Modeling |

MEP Modeler |

Graphisoft |

3D MEP Modeling |

HydraCAD |

Hydratec |

3D Fire Sprinkler Design and Modeling |

FireCad |

Mc4 Software |

Fire Piping Network Design and Modeling |

CAD-Duct |

Micro Application |

3D Detailed MEP Modeling |

Vectorworks Designer |

Nemetschek |

3D Architectural Modeling |

RISA |

RISATechnologies |

Full suite of 2D and 3D Structural Design Applications |

Tekla Structures |

Tekla |

3D Detailed Structural Modeling |

Vico Office |

Vico Software |

5D Modeling which can be used to generate cost and schedule data |

PowerCivil |

Bentley Systems |

Site Development |

Site Design, Site Planning |

Eagle Point |

Site Development |

BIM BENEFITS PER PROFESSION

Architects

The innovation of BIM started with architects, and many still see its value emerging from its use in the design phases. It is generally agreed that architects experience a high level of value along with many contractors (43%) and owners (41%), say.

Structural Engineers

It is generally accepted that structural engineers can extract high level of value from BIM. Elements such elements as steel columns, beams and trusses are frequently modeled by users. Contractors are the most likely (47%) parties to see structural engineers realizing significant benefits.

Construction Managers and General Contractors

Cost factor is an important criterion during construction. Budgets may be minimized considerably by reducing rework. Owners are the most likely (57%) parties to see a Construction Managers or General Contractor gaining highly on a project, most likely because the cost savings can be passed on.

Fabricators

As BIM resolves conflicts and builds confidence in building plans, many team members eye opportunities for value addition in fabrication. Wastage may be minimized by accurate fabrication of materials and time may be saved during the pre-assembly. Contractors (56%) are most likely to witness fabricators experiencing a higher value than architects (23%), engineers (38%) or owners (30%).

MEP Engineers

MEP engineers have ample instances to use BIM. Modeling of extensive elements such as duct systems and air handlers are feasible options, while smaller elements such as electrical switches and outlets might prove may be difficult. Unfortunately, a very few engineers (22%) collectively see MEP engineers enjoy high value. Nearly half of contractors (45%) believe MEP engineers see significant value.

Owners

Owners are the parties who ultimately enjoy all values collectively gained on a project. More than half (52%) of owners say they experience high value, but less than 30% of all other users believed this. The reason could be that other team members realize that owners are yet to see much value from BIM being used in operations and maintenance. Still, most owners believe they can tap the value of BIM during design and construction.

Specialty Contractors

Specialty sub-contractors may be assigned for executing some of the specific complexities of a project, but a few team members (23%) believe they are experiencing a high value from BIM. Generally, specialty subcontractors are smaller firms compared to general contractors and the costs of adopting BIM would not be practical. As BIM users utilize a variety of software applications, specialty subcontractors may face inter-operability issues and may incur added expenses to work within various models.

Building Product Manufacturers

A very few (11%) of building team members witness building product manufacturers gaining high value from BIM. This could impact team members’ belief that BPM's are not supplying sufficient BIM-related information yet.

LEVEL OF DETAILING/DEVELOPMENT [LOD]

LOD stands for level of detailing/development. There are 5 different levels which has been classified by the American institute of architects(AIA) in BIM Protocol (E202).

To simplify, the 5 different levels of LOD in industry’s interpretation are listed below:

» LOD 100 Conceptual modelling

» LOD 200 General modelling

» LOD 300 Accurate modelling & shop drawings

» LOD 400 Fabrication & Assembly

LOD100

Model Content Requirements

Overall building mass indicative of area, height, volume, location and orientation may be modeled in three dimensions or represented by other data.

Authorized Uses

Analysis- The Model may be analyzed based on volume, area and orientation by application of generalized performance criteria assigned to the representative model elements.

Cost Estimation

The model may be used to develop cost estimates based on current area, volume or similar conceptual estimating techniques (e.g., square feet of floor area, condominium unit, hospital bed, etc.)

Schedule

The model may be used for project phase scheduling and overall duration.

LOD 200

Model Content Requirements

Model Elements are modeled as generalized systems or assemblies with approximate quantities, size, shape, location, and orientation. Non-geometric information can also be attached to the model elements.

Authorized Uses

Analysis- The Model can be analyzed for performance of selected systems by application of generalized performance criteria assigned to the corresponding model elements.

Cost Estimating

The Model can be used to develop a cost estimate based on the approximate data furnished and conceptual estimating techniques (e.g., volume and quantity of elements or type of

System selected).

Schedule

The Model may be used to show ordered, time-scaled appearance of major elements and systems.

LOD 300

Model Content Requirements

Model elements are modeled as specific assemblies and are precise in quantity, size, shape, location, and orientation. Non-geometric information can also be attached to model elements.

Authorized Uses

Construction- Suitable for the derivation of traditional construction documents and shop drawings.

Analysis- The Model may be analyzed for performance of selected systems by applying specific performance criteria assigned to the corresponding Model Elements.

Cost Estimation

The Model may be used to develop a cost estimate based on the specific data provided and conceptual estimation techniques.

Schedule

The Model may be used to show an orderly, time-scaled appearance of detailed elements and systems.

LOD 400

Model Content Requirements

Model elements are modeled as specific assemblies that are precise in size, shape, location, quantity, and orientation with complete fabrication, assembly, and detailing information. Non-geometric information can also be attached to model elements.

Authorized Uses

Construction- Model elements are considered as virtual representations of the proposed element and are suitable for construction.

Analysis-The Model can be analyzed for performance of approved selected systems based on specific model elements.

Cost Estimation

Costs are based on the actual cost of specific components during procurement.

Schedule

The Model can be used to show an orderly, time-scaled appearance of detailed specific elements and systems including construction means and methods.

LOD 500

Model Content Requirements

Model Elements are modeled as constructed assemblies which are actual and accurate in size, shape, location, quantity, and orientation. Non-geometric information can also be attached to modeled elements.

Authorized Uses

General Usage-The model can be used to maintain, alter and add to the project, but only to the extent consistent with any licenses granted in the Agreement or as specified in a separate licensing agreement.

With the construction industry facing recessions, intelligent players are adopting BIM to provide them with a competitive advantage over their counterparts. Most of the organizations using BIM normally have a positive feedback about its effect on their business. BIM is being currently employed by professionals on all building types from the simplest warehouse to many of the most complex new buildings.

The Industry Foundation Classes (IFC/ifcXML) are an open specification for Building Information Modeling and are used to share and exchange BIM in a neutral format among various software applications. GBxml is an emerging schema, a subset of the Building Information Modeling efforts, focused on green building design and operation.

Although there are many difficulties, two of the main hurdles in adopting BIM technology are training and costs.

Training: Receiving adequate training is the greatest challenge to adopting BIM. This could be particularly difficult because only a limited number of users might be having an expert background that could be used as a training resource.

Costs: Cost of software and required hardware upgrades also form significant hurdles in the adoption of BIM technology.

BIM Outsourcing

Considering the advantages of adopting BIM technology, handling the work in-house would most probably nullify the advantages due to the involvement of training time & costs, hardware upgrade costs, software costs, etc.

Hence, BIM adopters are finding outsourcing BIM work, to countries like India, more advantageous than handling the work in-house.