Our Steel Detailing Services convert structural design intent into accurate, fabrication-ready, and erection-friendly documentation that supports efficient steel manufacturing and installation. The service focuses on translating structural engineering inputs into coordinated, constructible drawings and BIM-based models that guide fabricators and erection teams throughout the project lifecycle.

The scope of work includes the development of shop drawings, erection drawings, connection details, and 3D steel BIM models aligned with approved structural designs, project specifications, fabrication standards, and construction sequencing requirements. Detailing outputs are prepared to ensure dimensional accuracy, connection integrity, and compliance with applicable codes and tolerances. With experienced structural engineers and a structured QC process, we ensure accuracy, consistency, and coordination across all project stages. Each deliverable is developed with a clear focus on buildability, coordination, and cost control.

Our Steel Detailing Service Capabilities

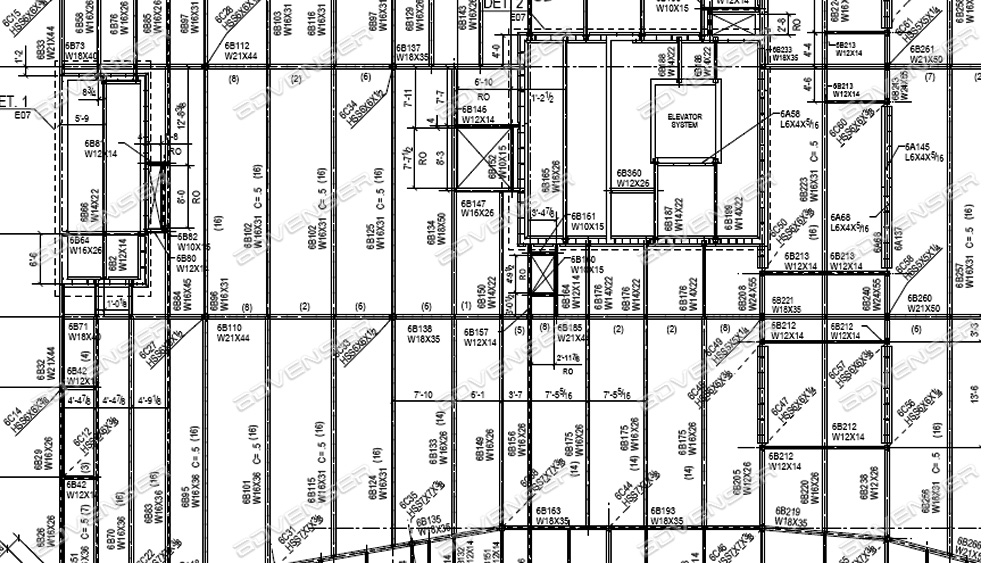

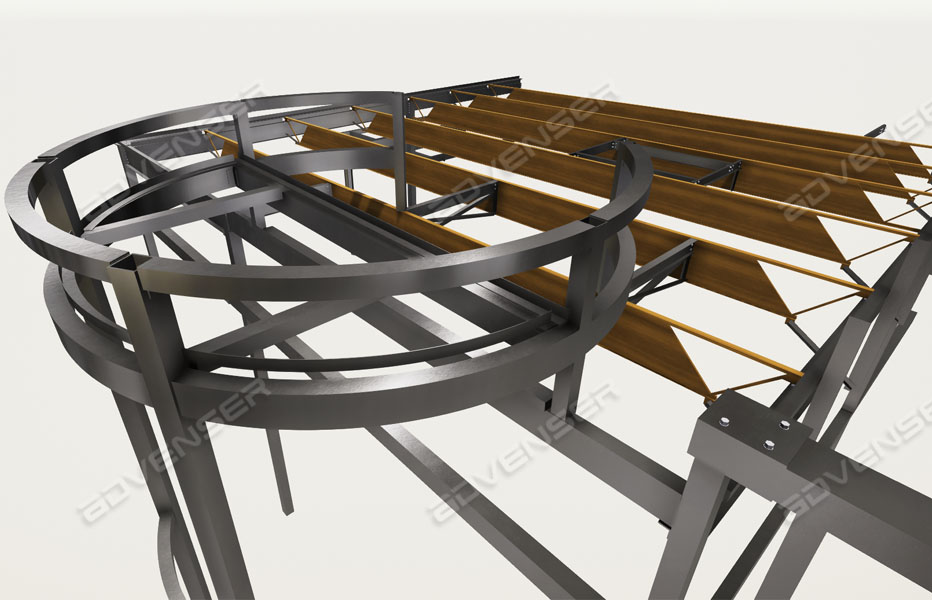

Structural Steel Shop Drawings

Shop drawings are developed for beams, columns, bracings, trusses, stairs, handrails, platforms, and miscellaneous steel components. Each drawing includes precise dimensions, member profiles, connection references, bolt and weld details, and fabrication notes to support accurate and efficient shop production.

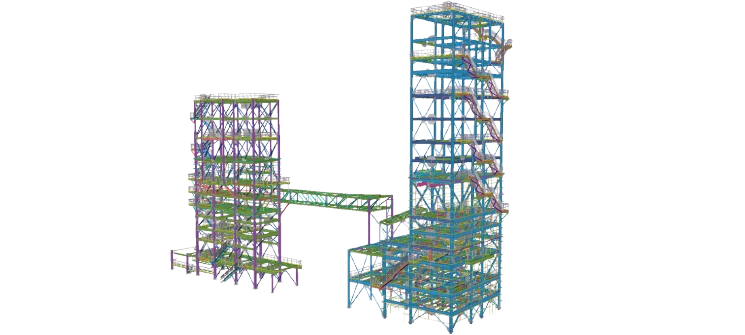

Erection Drawings & Assembly Plans

Erection drawings define member locations, grid references, elevations, splice points, and anchorage details required for on-site assembly. These drawings support clear installation sequencing, reduce site-level ambiguity, and improve coordination between erection teams for safe and efficient steel installation.

Connection Detailing

Connection detailing covers bolted and welded joints, base plates, gusset plates, stiffeners, and splice connections. Each detail is developed to ensure structural performance, fabrication feasibility, and compliance with applicable design standards and construction tolerances.

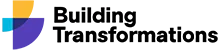

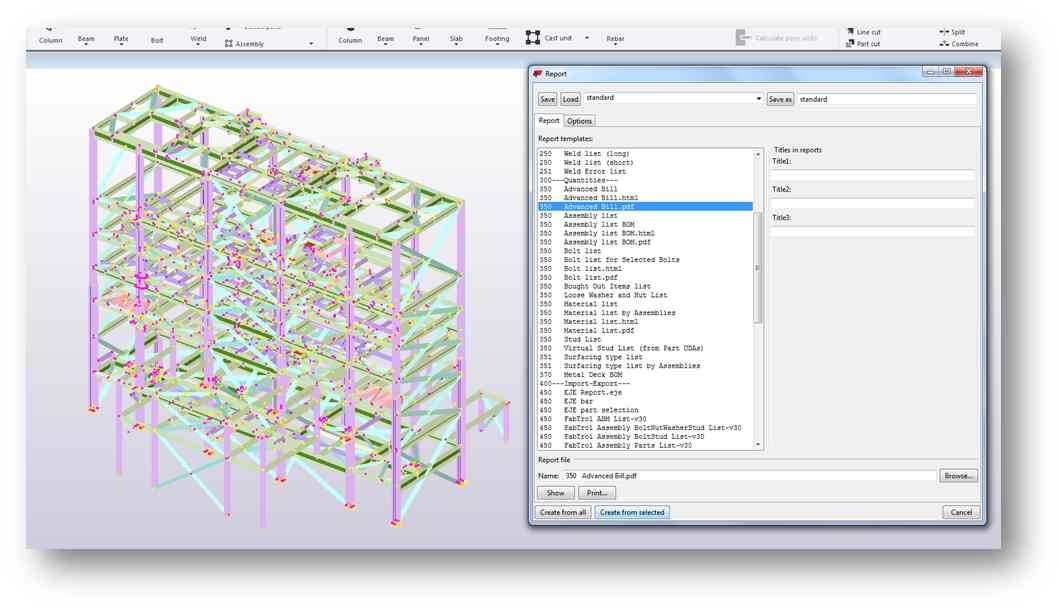

3D Steel BIM Modeling & Coordination

3D steel BIM models are created to represent structural elements with accuracy and intelligence. These models support coordination with architectural and MEP systems, enable clash detection, and improve constructability by resolving coordination issues before fabrication and erection.

Material Take-Offs & Bill of Materials

Material take-offs and Bills of Materials are extracted from coordinated models and drawings to provide accurate quantities of steel members, plates, bolts, and accessories. These outputs support procurement planning, cost control, and efficient material management throughout the project.

CNC & Fabrication Data Outputs

Fabrication-ready digital files such as DSTV, DXF, and NC formats are produced for CNC and automated fabrication systems. These outputs enable direct machine integration, reduce manual data handling, and support faster, more accurate steel manufacturing workflows.