Transform industrial facilities into accurate, data-driven digital assets using BIM-based plant digitization. By combining reality capture technologies such as laser scanning and photogrammetry with intelligent 3D BIM modeling, this approach delivers reliable digital representations of physical assets, layouts, and systems. The result is better planning, clearer understanding of existing conditions, and improved decision-making across project teams.

Industrial digitization replaces outdated drawings and scattered records with verified as-built BIM models. Teams gain access to accurate geometry, organized asset information, and searchable documentation, helping reduce rework, minimize errors, and support efficient project execution and long-term facility management. This digital foundation supports renovation, retrofit, expansion, and maintenance activities by providing dependable as-is information. It also enables smoother collaboration between engineering, construction, and operations teams throughout the facility lifecycle.

Core Capabilities

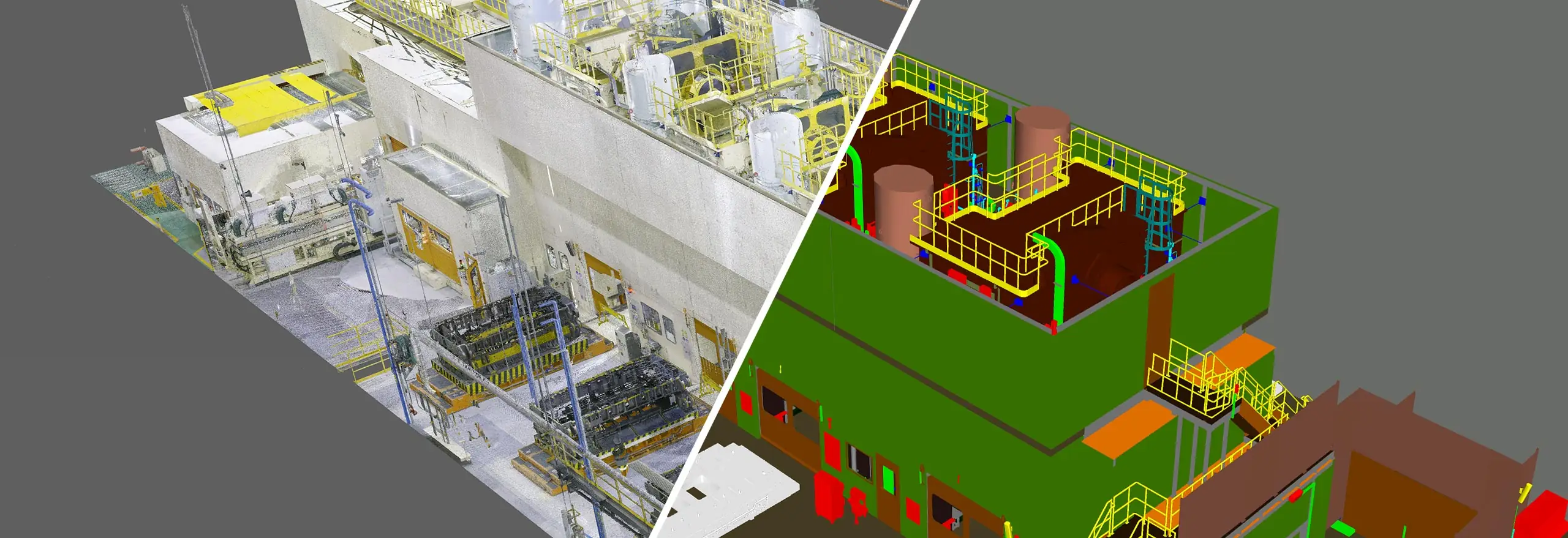

LiDAR & Reality Capture

High-density terrestrial/mobile LiDAR and imagery collect millimeter-grade data across buildings, production lines, pipe racks, cable trays, tanks, and mezzanines. Scan plans address access, safety, reflectivity, and line-of-sight to ensure full coverage with minimal disruption.

Point Cloud Registration & QA

Point clouds are registered, aligned to plant coordinates, and validated for accuracy, completeness, and noise. Deliverables support E57/RCP/RCS and downstream modeling without format friction.

Point Cloud to BIM / Plant Models

As-is, object-based models are developed in Revit, Plant 3D (AutoCAD), Navisworks, and IFC, with discipline segregation for piping, HVAC, electrical, structure, equipment, and architectural elements. Modeling follows fit-for-purpose LOD/LOI, supporting coordination, prefabrication, and field installation.

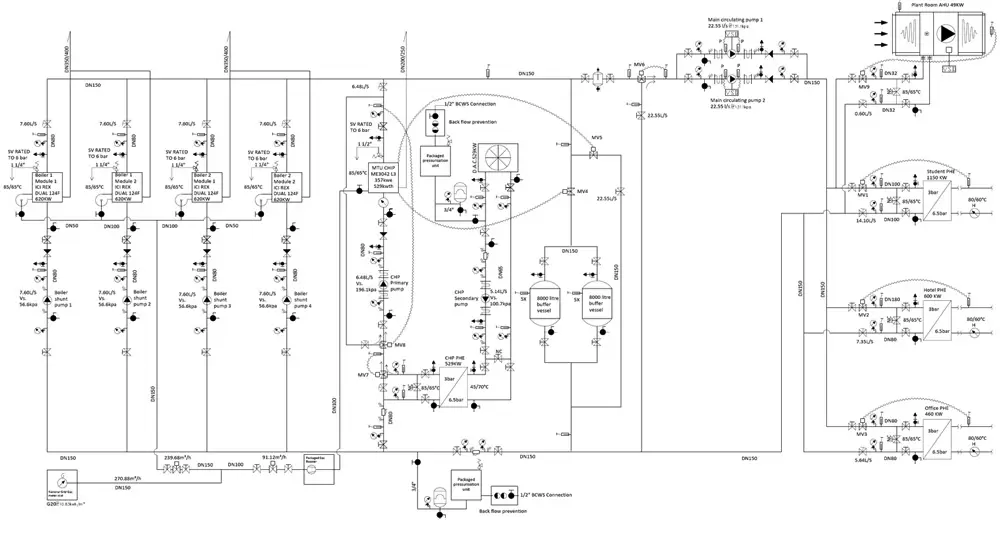

P&ID / Isometrics / Spools

Digitally author or update P&IDs, GAs, isometrics, and spool drawings aligned to the model and plant standards. Outputs include weld maps, BOMs/MTOs, supports/hangers, and valve/instrument lists for procurement and construction.

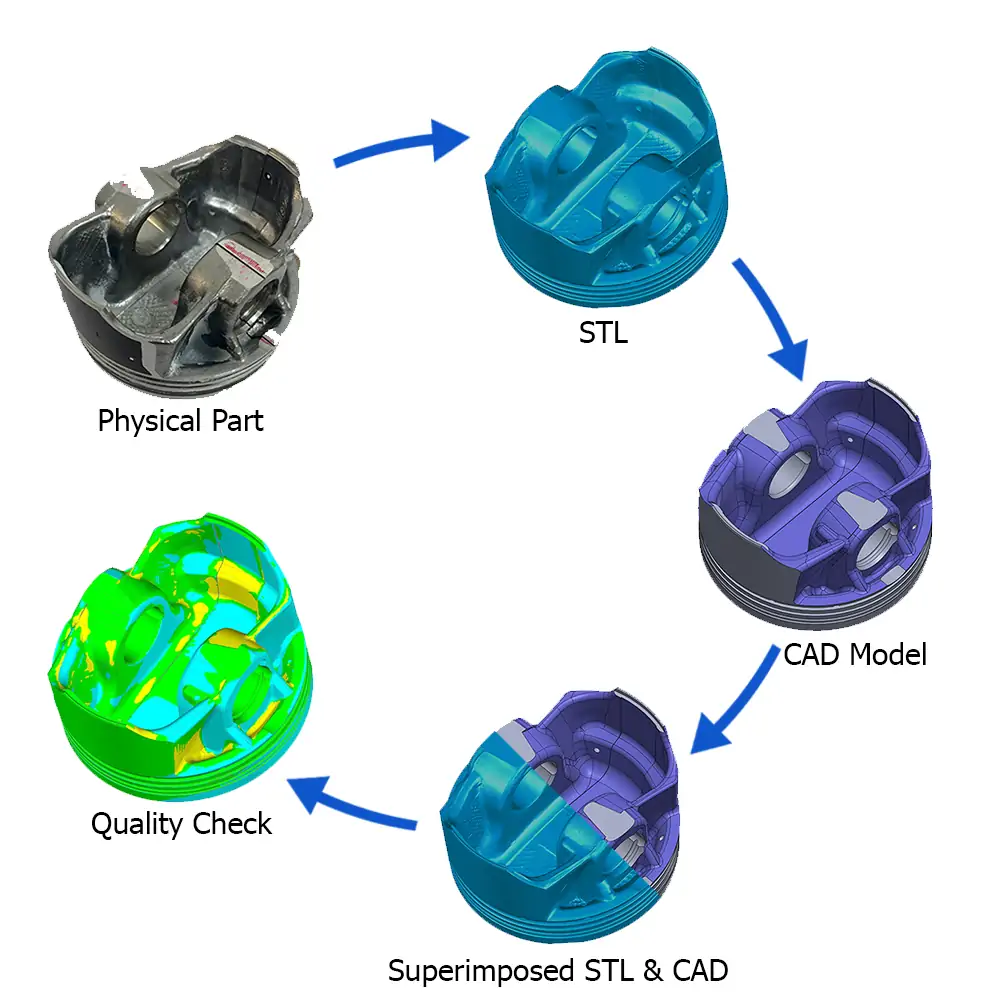

Reverse Engineering & Redesign Support

Legacy or undocumented parts are reconstructed into solids/surfaces for repair, replacement, or optimization. Optional tolerance studies confirm fit-up before fabrication.

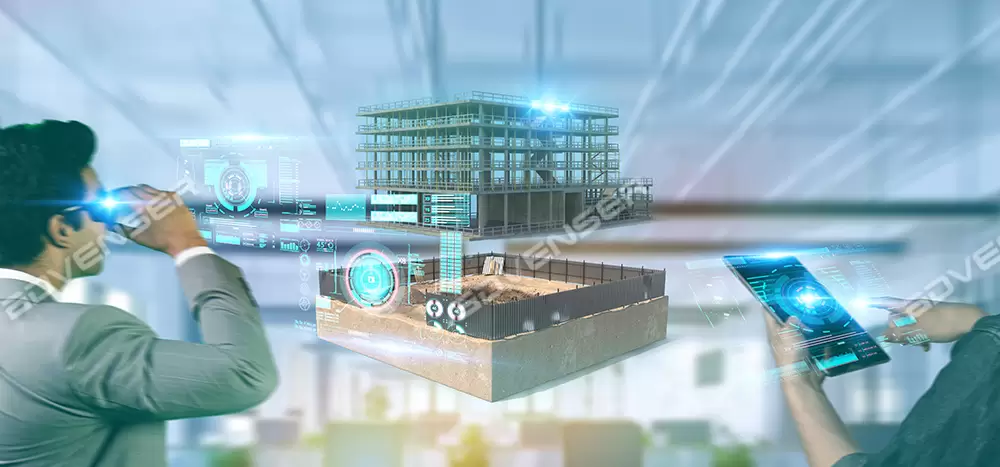

Digital Twin & FM Readiness

Models are enriched with asset IDs, metadata, and classification (COBie/IFC/UniClass) for integration with CMMS/EAM platforms. Data structures anticipate sensors, telemetry, and analytics, enabling condition-based maintenance and performance tracking.