We provide Architectural BIM, VDC, and CAD services that turn design intent into accurate, build-ready models. Our team delivers 3D modeling, construction documentation, 2D drafting, detailing, CAD conversion, and point-cloud–based models, developed to align with your project standards and budget. With experienced architects and a structured quality-check process, we ensure accuracy, consistency, and smooth coordination for architects, contractors, builders, and engineering teams.

Our BIM-led approach offers clearer visualization and better decision-making compared to traditional 2D methods. Renderings, walkthroughs, and simple sequencing all come from the same coordinated model, helping your project move from concept to construction with fewer errors, faster reviews, and improved efficiency.

Our Architectural BIM / VDC Services

BIM Design Development

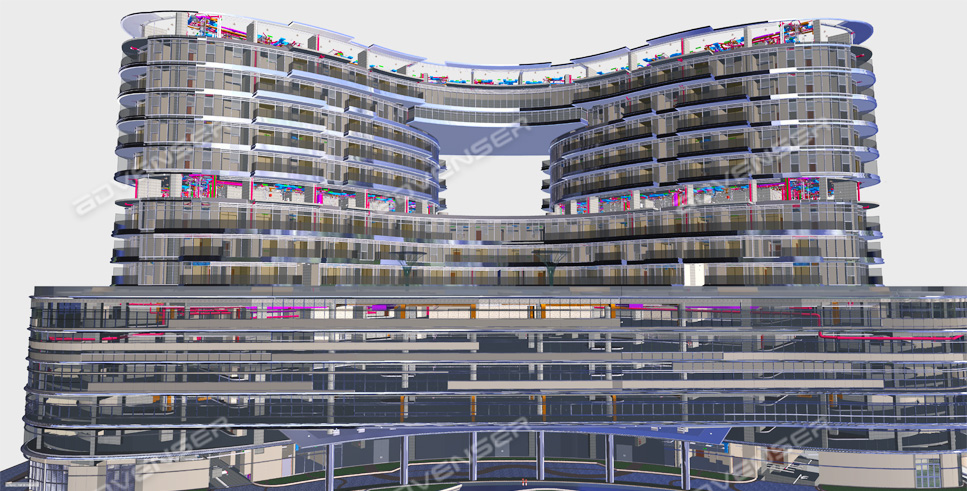

BIM Design Development strengthens the transition from early concepts to detailed design by combining visualization, analysis, and technical refinement in a coordinated 3D environment. The model supports design option studies, spatial validation, code and clearance checks, façade detailing, and performance analysis. With accurate geometry and early quantity insights, stakeholders can evaluate design choices confidently and finalize details with clarity and precision.

Revit 3D Modeling

Revit 3D Modeling provides a parametric, data-rich digital representation of the building that supports coordination, simulation, scheduling, and documentation. Architectural, structural, and MEP elements are modeled to the required LOD, ensuring accuracy at every stage. The model becomes a single source of truth for design reviews, clash detection, quantity extraction, and construction planning, improving communication and reducing errors across teams.

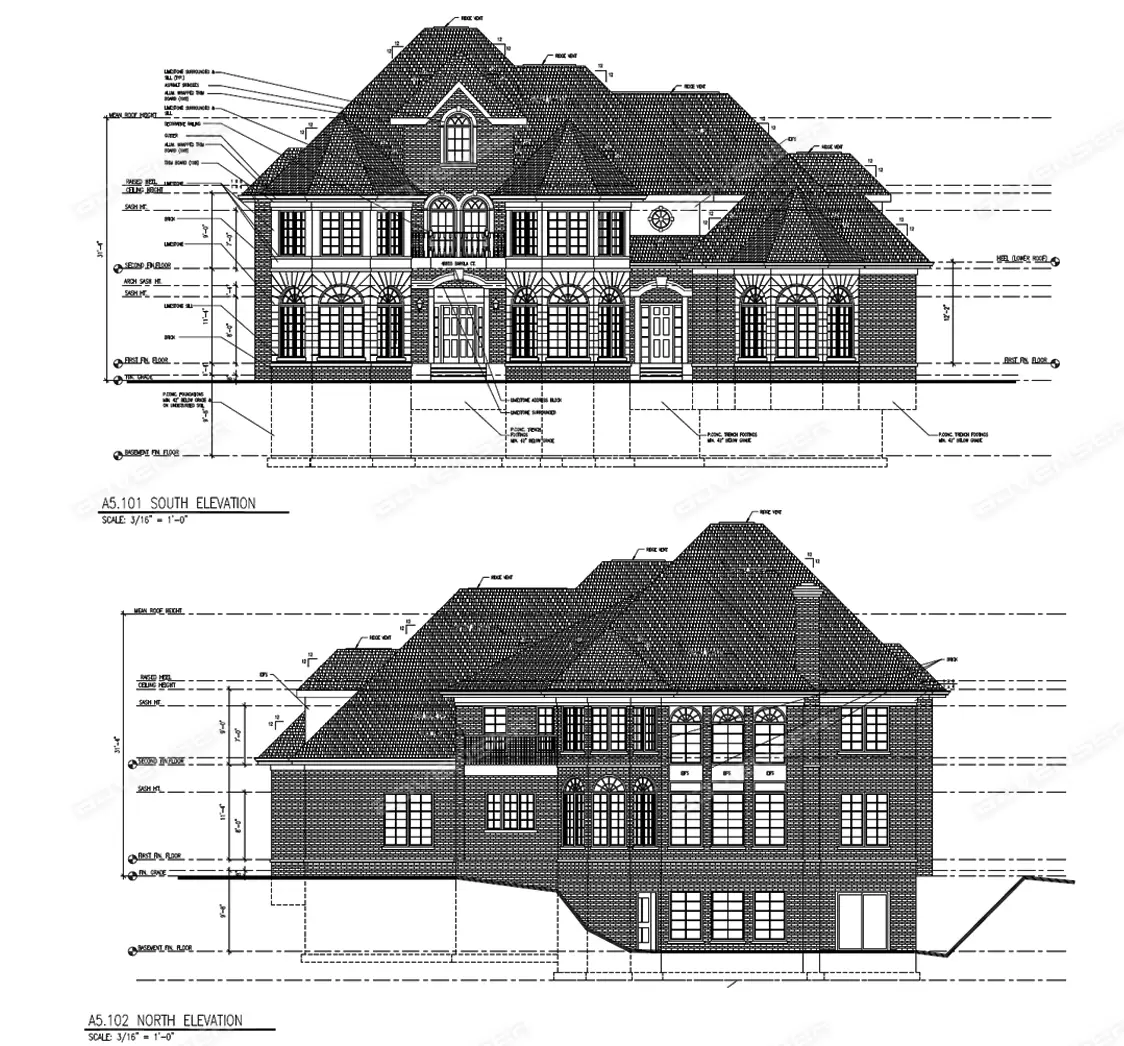

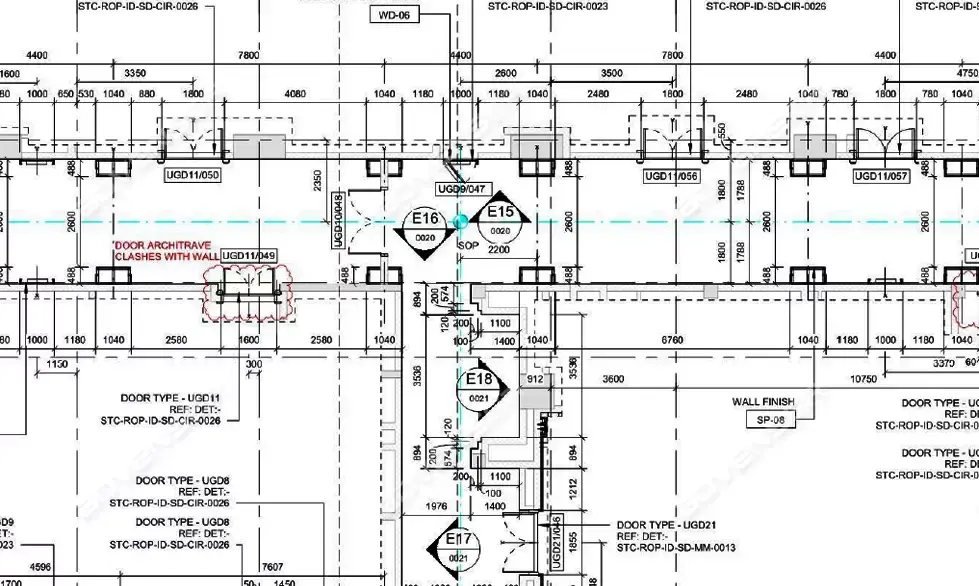

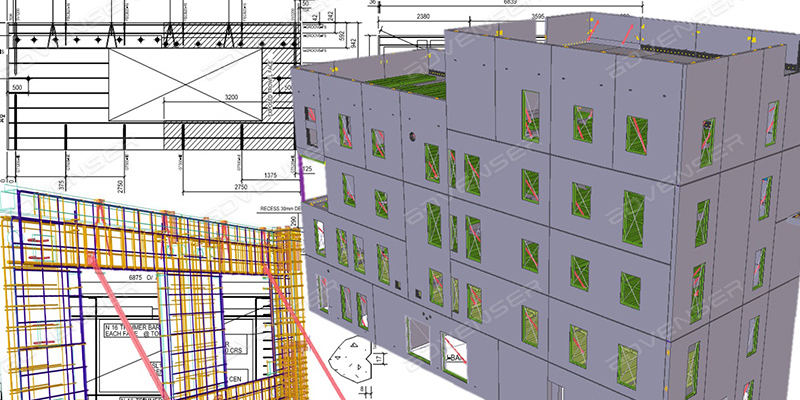

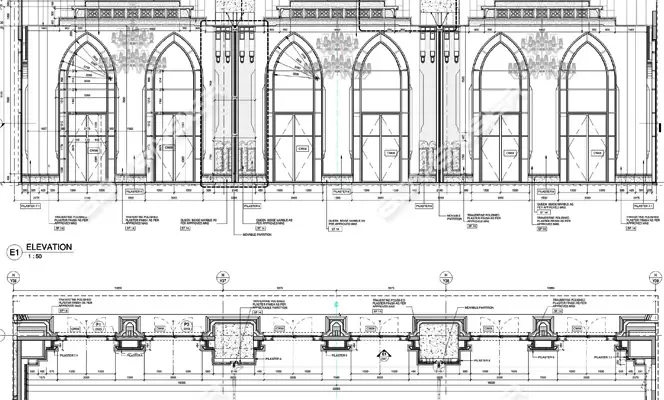

Construction Documentation

Construction Documentation translates the coordinated BIM model into clear, build-ready drawings that contractors can rely on. Plans, elevations, sections, assemblies, interior details, and annotated sheets are extracted directly from the model to ensure consistency across every document. This approach eliminates drawing discrepancies, speeds up the review process, and delivers a reliable package for submittals, permitting, and on-site execution.

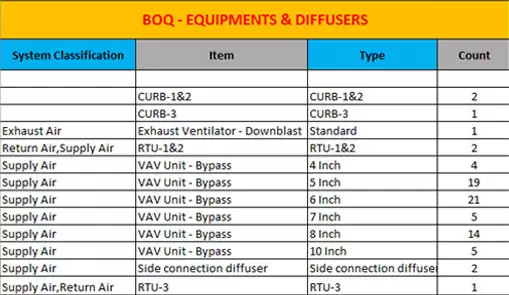

Quantity Takeoff Services

Quantity Takeoff Services use BIM intelligence to extract accurate quantities for materials, components, and assemblies. With precise model-based measurements, teams gain reliable data for budgeting, procurement, and cost planning. The automated extraction process reduces manual errors, speeds up estimation, and provides real-time visibility into quantity variations throughout the design and construction phases.

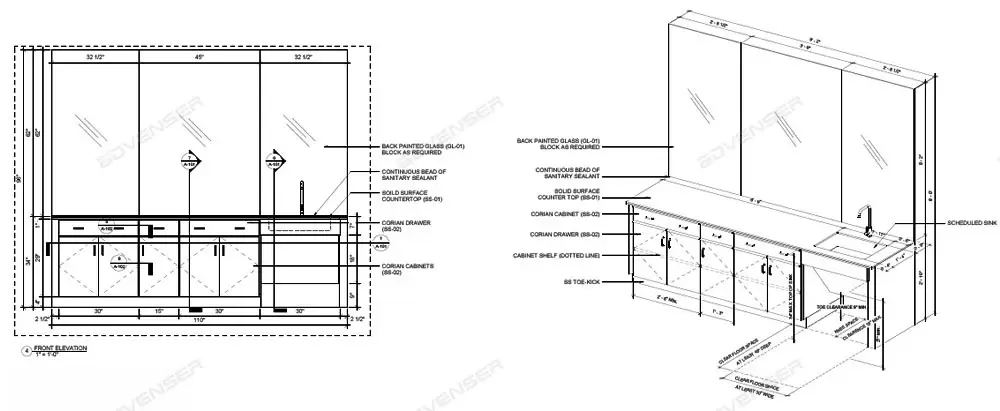

Millwork Modeling and Shop Drawings

Millwork Modeling and Shop Drawings focus on developing fabrication-ready representations of casework, joinery elements, partitions, and custom interior components. Each element is modeled with precise dimensions, fittings, and material details to ensure accurate manufacturing. The outputs include shop drawings, cut lists, and setting-out information that enable seamless coordination between designers, fabricators, and installation teams.

As-Built Drafting

As-Built Drafting captures the final built condition of a project and converts it into accurate, clean CAD or BIM documentation. All changes made during construction are reflected in updated drawings and models. This ensures facilities have reliable records for maintenance, renovations, compliance, and future planning, making as-built documentation essential for long-term building management.

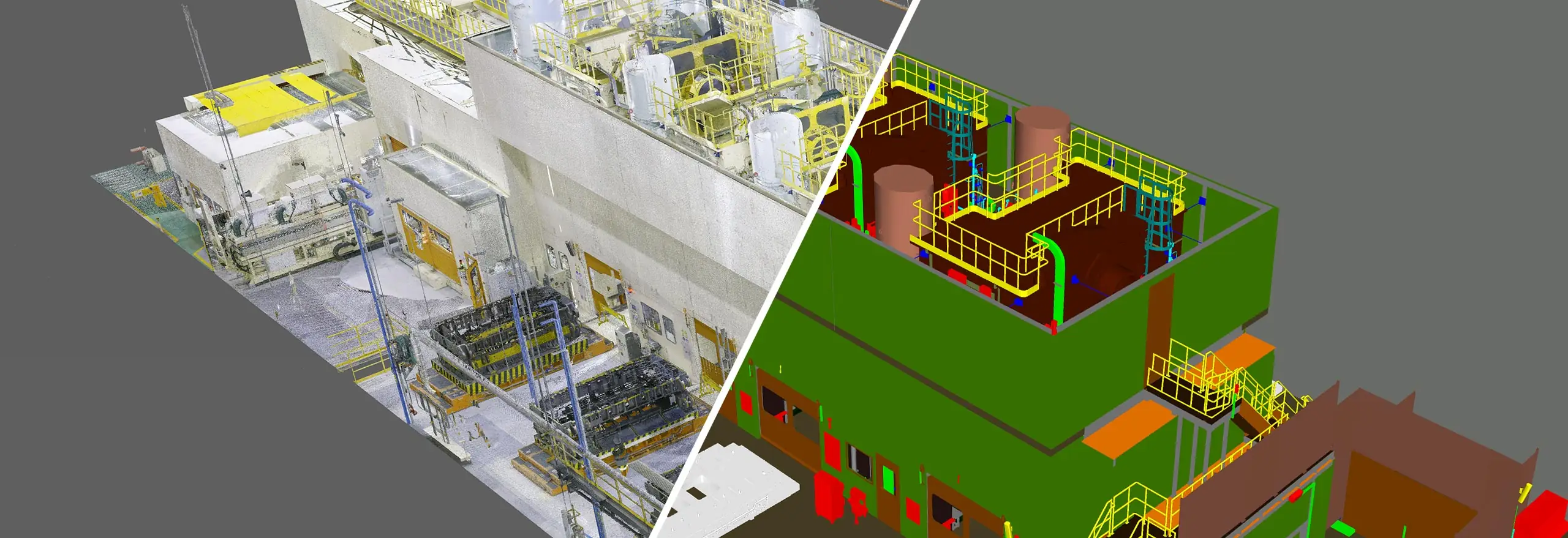

Point Cloud Scan to BIM

Point Cloud Scan to BIM converts 3D laser scan data into precise BIM models that accurately represent real-world conditions. The workflow covers point cloud registration, cleanup, and detailed modeling of architectural, structural, and MEP elements. These models are ideal for renovation, retrofitting, heritage conservation, facility surveys, and clash-free planning, providing dependable insights for project teams working with existing structures.

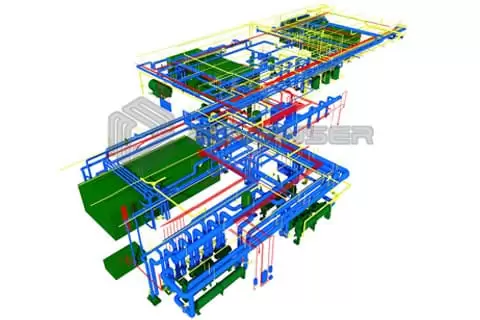

BIM for Modular Construction

BIM for Modular Construction supports the design, coordination, and fabrication of modular units through highly detailed and standardized models. The BIM environment enables precision in module sizing, MEP integration, clash avoidance, and assembly sequencing. By defining every component digitally before production, teams achieve faster project delivery, reduced waste, and smoother on-site installation.

2D Drafting Services

2D Drafting Services provide accurate CAD drawings for plans, elevations, sections, details, and documentation based on design inputs, sketches, or BIM models. Clean drafting practices and consistent standards ensure clarity and readability for construction teams, permitting authorities, and consultants. The service supports projects requiring traditional drawing formats while maintaining precision and compliance with industry norms.

Interior 3D Modeling

Interior 3D Modeling creates visually accurate and dimensionally precise digital representations of interior spaces. Materials, textures, lighting, furniture, and fixtures are modeled to reflect the design intent clearly. This enables designers and clients to visualize layouts, evaluate concepts, and finalize interior schemes with confidence before moving into documentation or fabrication.

Presentation Modeling

Presentation Modeling focuses on developing high-quality 3D models that communicate design intent visually for clients, stakeholders, and marketing teams. These models include detailed geometry, materials, lighting effects, and aesthetic enhancements suitable for renderings, walkthroughs, and concept presentations. The result is a compelling visual asset that supports approvals and design storytelling.

BIM for Prefabrication

BIM for Prefabrication enables accurate modeling of building components intended for off-site manufacturing. Every element including structural, architectural, or MEP, is modeled to fabrication tolerances, with embedded data that supports production and assembly. This digital precision helps manufacturers reduce errors, optimize material use, and streamline installation, ensuring prefabricated components fit seamlessly during on-site assembly.